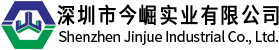

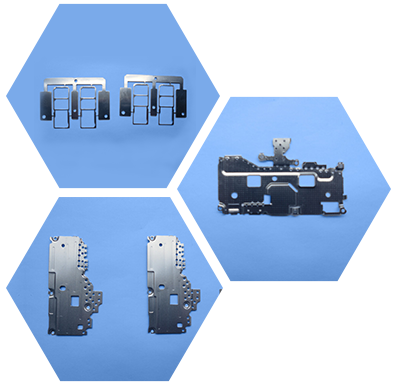

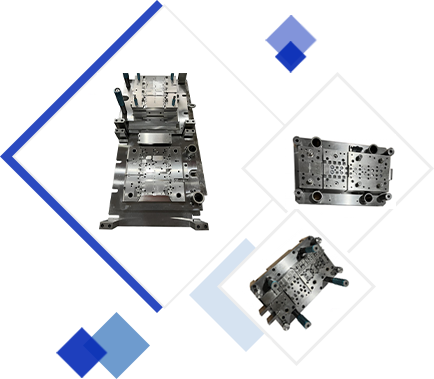

Shenzhen Jinjue Industrial Co., Ltd. was established in August 2016. Before that, it was a professional supplier of precision electronic stamping dies, and later transformed into a professional ODM/OEM manufacturer dedicated to precision electronic hardware stamping. Jinjue is mainly engaged in and provides solutions for precision stamping parts for mobile phones and 5G communications; various types of radiator fin/heat sink stamping parts; high-voltage terminal stamping parts, etc. The mobile phone and 5G communication stamping parts produced by Jinjue include shielding cover, backlight, antenna shrapnel, mobile phone midplane, mobile phone camera decoration steel sheet, and mobile phone card holder steel sheet.

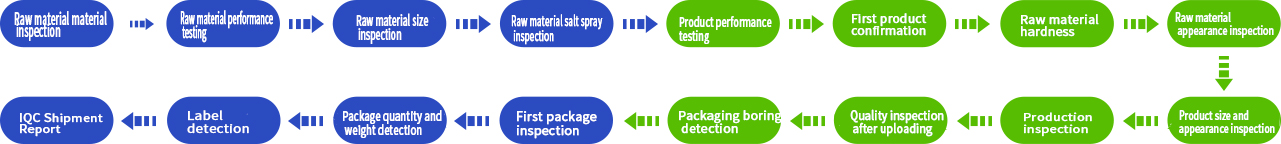

Jinjue implements the quality system ISO9001:2015, and continues to promote 6S management activities in the factory to provide customers with continuous high-quality products and services. As of January 2019, there are 6 high-precision presses (imported from Japan and Taiwan), with more than 30 employees and more than 10 professional and technical personnel; among them, 3 senior engineers with more than 10 years of design and R&D capabilities and rich experience in manufacturing molds There are 8 intermediate engineers, 6 engineers and technicians with professional mold maintenance skills.

The Jinjue team has many years of actual production experience accumulated in the precision stamping industry. It overcomes difficulties and is good at technically overcoming high-precision and difficult-to-complex hardware. The thickness of continuous stamping materials can reach 0.05-3.0MM, and the dimensional accuracy of product blanking can reach ±0.01MM. Actively participate in the preliminary design of precision metal stamping parts for customers' products to ensure that the development cycle of new products is shortened and the cost of mass production products is optimized. Especially with its own mold room and a team that manufactures precision stamping molds, Jinjue can provide a one-stop solution from design, mold opening, production, post-processing, and assembly/packaging. It can implement in-mold automatic tapping and molds. Technical requirements such as internal automatic riveting have saved customers a lot of time and cost.

The product materials used by Jinjue include but are not limited to beryllium copper (heat treatment required), titanium copper, phosphor bronze, stainless steel, spring steel, etc.; surface treatments that can be provided include but are not limited to gold plating, silver plating, nickel plating, tin plating, Ultrasonic cleaning of oil stains, etc.; packaging services that can be provided include but are not limited to tape and roll packaging, carrier tape packaging, blister box packaging, and so on.

Jinjue is committed to becoming the world's most professional supplier of electronic precision stamping parts, and it is our responsibility to assist customers in enhancing their competitiveness. We look forward to your consultation and cooperation!