CNC hardware processing manufacturers know that the temperature environment of equipment processing will have a great impact on the requirements of the processing technology. Overheating will cause deformation of the workpiece, which will seriously affect the processing quality of parts, especially for copper products, the processing temperature The control requirements are very high, because the cutting process of copper parts is easy to heat up;

In the process of precision parts processing, processing will cause a lot of heat sources. Processing machinery, processing tools, and processed parts are easily deformed by this temperature. The accuracy of CNC machinery, the accuracy of tools, and the accuracy of processed parts will all be affected. , Under the action of heat, relative displacement between the workpiece and the tool will also occur, forming a machining deviation, resulting in the impact of machining accuracy;

Processing accuracy is the embodiment of the company’s hard power for mechanical hardware processing manufacturers. Why do users choose more authoritative and professional processing companies for cooperation? The purpose is to pursue stable processing accuracy and stable processing efficiency to meet the customer’s delivery cycle. However, the accuracy error caused by thermal deformation has been high for many processing manufacturers for many years, and even reached half in the processing of some special parts;

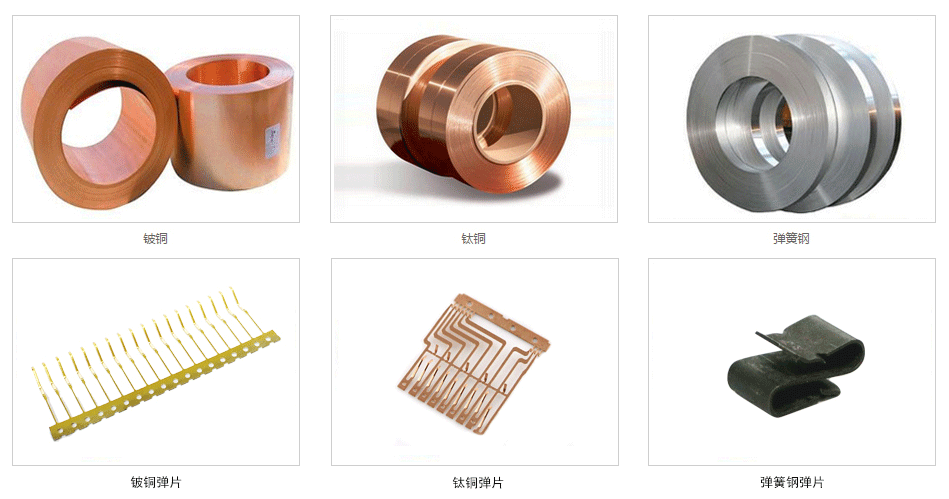

In order to prevent the temperature from affecting the processing accuracy, machining manufacturers generally strictly control the reference temperature of the processing environment and specify the deviation boundary of the temperature control. The constant temperature state of 20±0.1°C is relatively common. However, for the humidity of the air, many hardware However, processing manufacturers have no obvious requirements. For the processing of special parts, such as copper products, under normal circumstances, they are processed under constant temperature and humidity. The temperature is required to be 20±0.2°C, and the relative humidity is 45%±5%;

With the development of mechanical processing manufacturers, manufacturers will also become more and more developed in the processing temperature control process. The influence of temperature on the process is becoming less and less, but the accuracy is getting higher and higher.