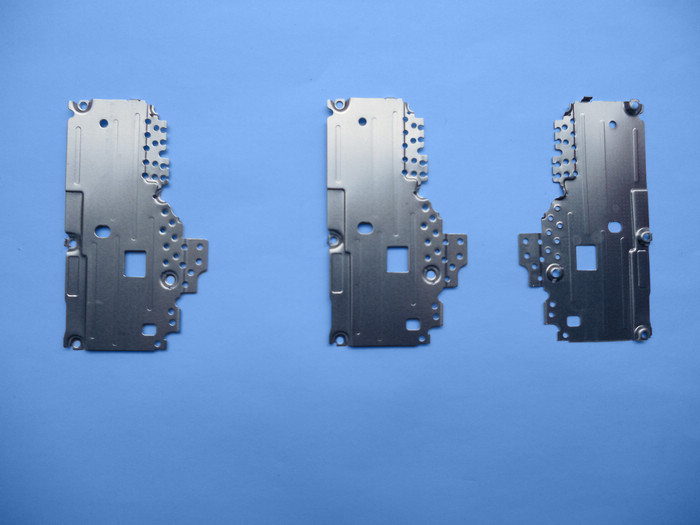

Metal machining parts edges and corners

1, unfilled corner radius R5;

2, all unfilled chamfers are 2*45°;

3, sharp corners, sharp corners, obtuse edges and obtuse;

Mechanical processing coating requirements

1. The time interval between shot blasting or manual derusting of the surface to be coated and primer coating should not be more than 6 hours;

2, all steel parts that need to be painted must be cleaned of rust, oxide scale, dust, grease, nicknames, salt and other dirt before painting;

3. The contact surface of the riveting parts must be coated with anti-rust paint with a thickness of 30~40um on the link. The lap edge should be sealed with putty or adhesive. The primer damaged by the processing and welding must be repainted;

4. Before removing rust, use organic solvents, lye, emulsifier, steam, etc. to remove high-quality and dirt on the surface of steel parts;