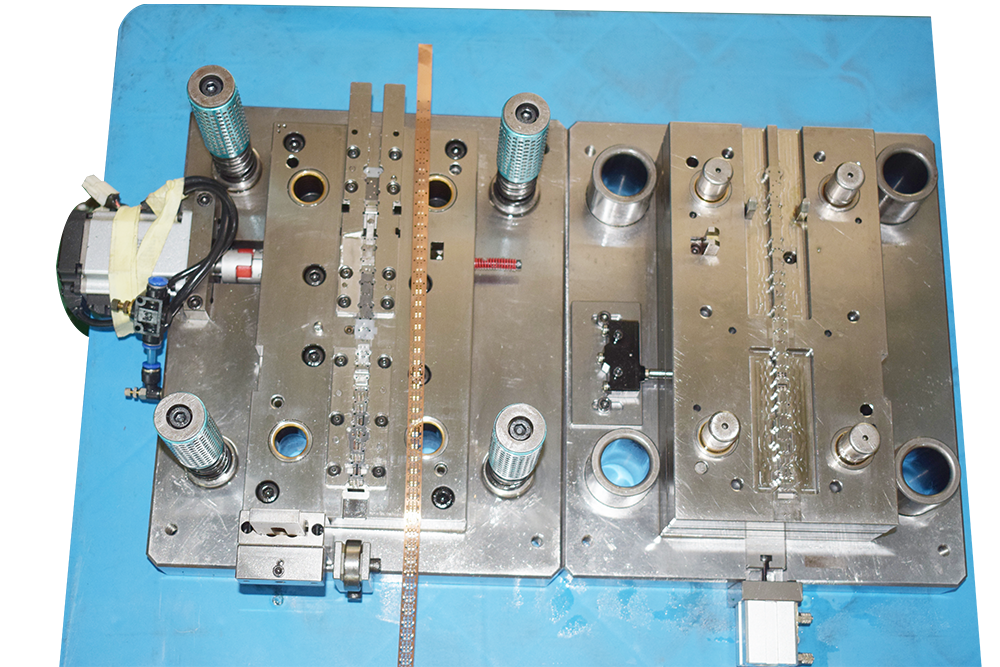

Product name: In-mold riveting automation mold

Metal molds are used in industrial production to use various presses and special tools mounted on the presses to make metal materials into parts or products of the required shape through pressure. These special tools are collectively referred to as hardware molds.

The various tools and products used in our daily production and life, ranging from the base of the machine tool and the body shell, to a small screw, button and the shell of various household appliances, are all closely related to the mold. The shape of the mold determines the appearance of these products, and the processing quality and precision of the mold also determines the quality of these products. Because of the different materials, appearance, specifications and uses of various products, molds are divided into non-plastic molds such as casting molds, forging molds, die-casting molds, and stamping molds, as well as plastic molds. Precision stamping parts, new energy stamping parts, metal stamping dies

The new development is that the external computer is directly connected to the CNC machine tool through the RS-232C serial port, and the NC program is directly transmitted quickly and accurately, and the external computer can be connected to multiple CNC machine tools with the same or different control systems. , To share information, and to manage the information in the production process in the CNC section composed of multiple machine tools, so as to reduce the production preparation, especially the preparation time of the CNC NC program. With the maturity of CAD/CAM and integrated management software, as well as the increase in demand for flexible manufacturing systems, the use of CNC machine tools, from stand-alone use to computer integrated management, is the development direction of the production and processing industry technology. Precision stamping parts, new energy stamping parts, metal stamping dies

It is based on the above problems in the mechanical processing industry, as well as the introduction of new technologies and concepts in the CAD/CAM system, the continuous introduction of MIS systems and ERP systems, and further, the development of CIMS technology in China, the information integration at the bottom of the workshop is the most important Heavy. To this end, we have designed and developed various products for the integration of workshop processing equipment as described below.