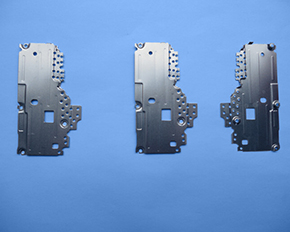

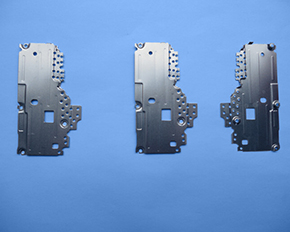

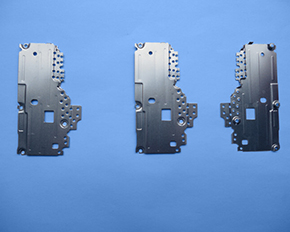

Product name: Stamping parts

Jinjue is mainly engaged in the production of precision stamping parts for mobile phones and 5G communications, and specializes in providing solutions for precision stamping parts such as shielding covers, antenna shrapnels, mobile phone plates, mobile phone camera decorative parts steel sheets and mobile phone card holder steel sheets.

The shielding cover is mainly used in mobile phones, GPS and other fields to prevent electromagnetic interference (EMI) and shield the components and LCM on the PCB. The flatness of the shielding cover and backlight produced by Jinjue is strictly controlled within the tolerance range of 0.05mm to ensure its easy tinning performance and good shielding effect. We can provide stretch forming and one piece according to customer requirements and drawings. Two-piece solution with frame and frame + cover. Especially for the frame + cover two-piece shield, the SMT pick-up point of the frame part produced by Jinjue can be made into a separate type and embedded on the frame part, which is convenient for the later maintenance of the chips and electronic components inside. According to customer requirements, the materials used by Jinsheng are tin-plated steel, nickel silver, stainless steel, etc.; the available packaging methods with flat surface requirements on the bottom of the frame parts include carrier tape packaging, blister tray packaging, and the cover can be PE Bulk packaging.

Antenna shrapnel metal shrapnel can be divided into round metal shrapnel, cross-shaped metal shrapnel, triangular metal shrapnel, and oval metal shrapnel according to their different shapes. The diameter ranges from 3mm to 20mm, and the strength ranges from 100g to 600gf. The antenna shrapnel produced by Jinjue includes gold-plated beryllium copper shrapnel, stainless steel shrapnel and phosphor bronze shrapnel, which are formed by continuous die stamping. The antenna shrapnel produced by Jinjue has an accuracy of ±0.01mm and 1 million anti-fatigue tests. The antenna shrapnel has a large number of products, and the product structure is relatively soft and has feet, which are prone to deformation and will not be overturned during cleaning. Jinjue uses self-prepared cleaning fluid, ultrasonic vibration cleaning and degreasing, and then 2-3 times of rinsing, followed by drying.

The middle plate of the mobile phone, the steel sheet of the decorative parts of the camera and the steel sheet of the card tray are mainly the stamping parts of the assembly structure inside the mobile phone, which play the role of fixing and supporting the main board, the camera and the SIM card. Jinjue’s mobile phone mid-plates, camera decoration steel sheets, and cato steel sheets are mainly made of stainless steel and are designed and produced according to customers' concepts and requirements. At present, the existing mobile phone midplanes generally have the shortcomings of being extremely flexible and prone to degumming after being encapsulated. The medium plate designed and manufactured by Jinjue meets the requirements of various precision and strength. There are several buckles on the periphery of the metal plate body. The buckles are formed by bending a circular boss to the same side. After gluing, the plastic accommodates the groove or flange in it to avoid degumming. The decorative steel sheet of the camera can be continuously stamped and pneumatically cut according to the required quantity of the material strip, which is convenient for customers to achieve the requirements of continuous injection molding of inserts and so on. Cato steel sheet can also be pneumatically cut according to the customer's injection quantity requirements, which is convenient for injection molding of inserts. Jinjue will provide tinning and other post-processing as well as packaging services for different requirements according to customer requirements.